If you feel like you need to mix and match strings to get the best out of your instrument, start by reading this guide from Franz Klanner, director of engineering and technology at Thomastik-Infeld

In the first part, we explained the theory behind the combining of different strings, answering questions such as: Is it even feasible to combine different strings? What are the resulting advantages and disadvantages? And what are the five factors that play an essential role when combining strings? In this blog post, we will shed light on the biggest misconceptions when combining different strings and will then answer the fascinating question of whether and how strings from different manufacturers and even different instruments can be combined.

WHAT ARE THE BIGGEST MISCONCEPTIONS WHEN COMBINING STRINGS?

One of the biggest misconceptions is the assumption that a larger string diameter leads to a higher string tension. But this is not the case. The string tension is calculated using the weight per length, i.e. the density and not the thickness of the material. A strip of silver of a certain strip thickness and width is approximately four times heavier than a strip of aluminum with the same measurements. What this means is that if you compare a silver-wound D-string with an aluminum-wound D-string of the same string tension, the silver-wound D-string is still much thinner, since silver has a higher density.

The second misconception is that thinner strings – meaning those with a smaller diameter – always have a better response than thicker strings. This is correct if the strings you are comparing have the same core and external winding material and the same string tension. However, if these properties differ, it’s no longer possible to make this assumption. The brilliance of the string also plays a decisive role for the bow response. Usually, a duller-sounding string responds better than a brilliant string, as there are fewer reflections of vibration on the bridge. Furthermore, a focused string responds better than a broader-sounding string.

Yet the crucial factors that affect the response are the core material and the outer winding material.

| Winding | Diameter | Bow response | Sliding Feel | Sound |

|---|---|---|---|---|

|

Aluminum |

larger |

better |

average |

more brilliant |

|

Silver |

smaller |

average |

increased |

average |

|

Chrome steel |

average |

inferior |

decreased |

darker |

Now that we have clarified the fundamental prerequisites for the combining of strings, three additional questions arise:

- Is it possible to combine strings from different product lines within one manufacturer’s range?

- Is it possible to combine strings from different manufacturers?

- Is it possible to combine strings from different instrument groups?

IS IT POSSIBLE TO COMBINE STRINGS FROM DIFFERENT PRODUCT LINES WITHIN ONE MANUFACTURER’S RANGE?

In the past, Thomastik-Infeld defined product lines according to their core type; for example, all products of the Dominant family have a core made of polyamide, while the Spirocore strings consist of a spiral rope core and the Precision line of a steel wire core.

Due to changing market demands, we began to combine core materials within one line of strings, in order to create brand new sound dimensions.

And it is for precisely this reason that is it indeed possible to combine strings from different product i.e. core lines with one another in order to achieve exactly that: the ideal sound dimensions and optimum handling for one’s individual needs. What is important is to take into account the above-mentioned factors, such as core and winding material, string tension, pitch stability and tonal break-in time.

IS IT POSSIBLE TO COMBINE STRINGS FROM DIFFERENT MANUFACTURERS?

Different manufacturers use different production techniques. This leads to different sound spectrums that, in turn, have a strong impact on the tonal life span when combined. If you decide to combine strings from different manufacturers anyway, it is crucial to select the correct tension. Warning: The indications for vibrating string lengths often vary between different string manufacturers, which can make it harder to compare them. Find all the details of what to look out for in our article “vibrating string length and string tension “.

IS IT POSSIBLE TO COMBINE STRINGS FROM DIFFERENT INSTRUMENT GROUPS?

For cello and bass, the answer is clear: NO.

But it is possible for violas and violins.

VIOLA STRINGS ON A VIOLIN?

Yes, this works. But only with the A-string.

First off: Why would anyone want to use a viola A-string on a violin? A-strings for violins are designed to emit a high degree of brilliance, whereas strings for violas sound warmer. Therefore, if the goal is to give your violin a warmer sound, you can use a viola A-string on the violin. The viola A-string also has better corrosion resistance if it is wound with chrome steel.

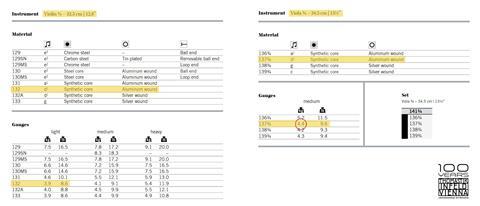

For a duller sound, we recommend the viola PI21 A-string (from the PI200 set), and the viola VI21 A-string for a brighter sound (from the VI200 set). All other viola strings, including synthetic viola A-strings, are not suitable for use on a violin, because the particular string tensions are much too low for the smaller instrument.

Warning: the suitability only applies to the combination of 4/4 viola strings with 4/4 violins. Conversely, 4/4 violin strings would obviously be too short for 4/4 violas. In order to use viola A-strings on a violin, it is necessary to shorten the string by around 5cm (2 inches) at the peg end. A well-sharpened string cutter is also recommended.

Of course, the correct string tension is also important. This topic has already been discussed in detail in the article ‘vibrating string length and string tension’. The vibrating string length (mensur) of a 4/4 violin is 32.5 cm. For a viola, it tends to lie between 37 and 38 cm on average. If you now compare the string tension of a 4/4 violin A-string with a 4/4 viola A-string, they obviously won’t match up at first glance. But since the string tension of the viola A-string was calculated for the longer mensur of the instrument, it will decrease correspondingly when winding it onto the shorter violin.

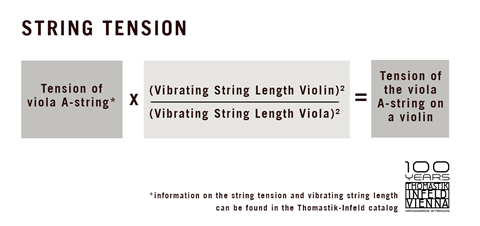

If you would like to calculate the string tension for an instrument equipped with new strings yourself, you can use the following formula:

CONVERSELY: CAN YOU ALSO USE VIOLIN STRINGS ON VIOLAS?

4/4 violin strings (32.5 cm mensur) are frequently used for 1/2 violas, as the mensur is identical for each. However, you usually need to complement this combination with a suitable viola C-string. Thomastik-Infeld offers the perfect string for this purpose: the 4/4 violin C-string VI05 from the VISION line. The same applies for a ¾ violin string on a ¼ viola. However, we currently do not have any ¾ violin C-strings in our range.

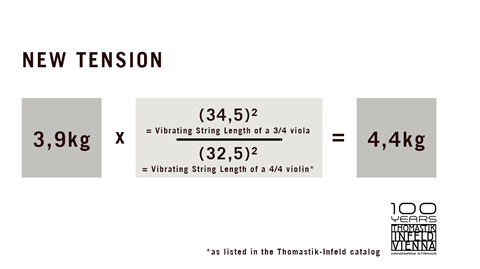

For a ¾ viola with a 34.5 cm mensur, you could also employ soft 4/4 violin strings (32.5 cm mensur). The length of the violin string should usually fit a viola too. However, the winding on the peg end of the violin G-string could come very close to the viola’s nut. Even though the mensur is different, the “soft” tension means that the string tensions ultimately match up. This means that if you usually opt for medium tension viola strings, a violin string of a “soft” tension (32.5 cm mensur) becomes a “medium” tension string on your viola (34.5 cm mensur). This should be applicable to all common violin strings (A, D, G). However, you would again have to find a suitable viola C-string in this case.

Here’s a practical example:

Using the Dominant D-string 132 with a string tension of 3.9 kg as the basis for the calculation:

NEW TENSION:

The newly calculated string tension of the 4/4 violin string for the ¾ viola thus equals the exact value listed in the Thomastik-Infeld catalog for the ¾ viola Dominant D-string:

No comments yet