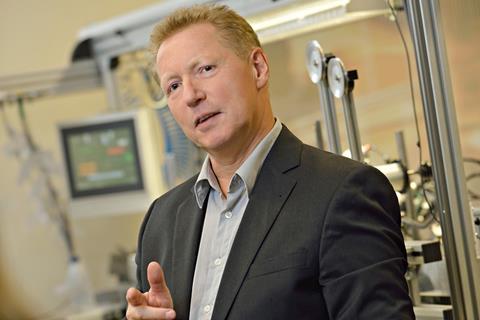

In the first of a new blog series for The Strad celebrating Thomastik-Infeld’s 100th anniversary, the Austrian string manufacturer’s director of engineering and technology, Franz Klanner, gives his recommendations for players who find their strings corroding too quickly

THE PROBLEM WITH CORROSION AND PERSPIRATION

It’s a well-known problem that aluminum-wound strings can corrode and unravel quickly. Why? Aluminum reacts with the sweat of your fingers. Even a little perspiration can cause your string to give up too fast! They unravel, get tarnished, go dark, get thicker and perfectly smooth shifts become harder when running over the worst of the damaged areas.

We wanted to get to the bottom of this, so we worked together with the dermatology department of the General Hospital in Vienna to analyze the composition of perspiration within different climates and age groups and in regard to other influences like stress and nutrition, to better apprehend the effect it has on different materials. By understanding the human side of the problem, we were able to find a technical solution within the string making process.

THE CORROSION-CHALLENGE IN A NUTSHELL

Sweat is aggressive, breaks down the outside of the string and soaks into the layers of the winding. That’s why cleaning the string is not really helping to stop the corrosion from the inside. It’s like dental decay slowly destroying the tooth inside out. We have approached this problem from two different angles to give our strings double power when it comes to extending their playing life.

DON’T SWEAT IT!

First we tested a variety of new as well as established materials to compound the ideal aluminum alloy making the string more perspiration resistant and stopping sweat from soaking in in the first place. After playing the string for a while the top layer can wear off a little. Therefore, step two was to develop and incorporate a protective interlayer to avoid sweat from penetrating the string on the inside altogether.

YOU KNOW WHAT I‘M TALKING ABOUT?

Then you are probably using an aluminum a and/or d-string.

MY RECOMMENDATION

To extend the life span of your strings I recommend using a silver-wound synthetic core d-string and a chrome-wound steel core a-string. For the violin a-string I suggest using the chrome-wound Vision medium VI02B string.

For a darker sound, use the chrome wound a-string PI21 which is included in the PI viola set PI200. When you are aiming for a more brilliant sound, I recommend the chrome wound a-string VI21 which is also part of the Vision viola set VI200. If you want to use the viola a-string on your violin shorten it for about 2 inches on the peg end side.

By the way, all these recommended a-strings have a steel core, so keep in mind to use a fine tuner! With all these strings we have brought one of our latest patents to life. By incorporating a special interlayer, we were able to increase the corrosion protection even more and managed to reduce the metallic sound at the same time. The result: these strings keep their warm timbre and dark sound for a long time, offer a great response and the tonal lifespan is significantly longer.

As for the d-string I suggest the silver-wound Vision Solo VIS03A or the silver-wound Peter Infeld PI03A. Both strings boast stability under changing climatic conditions and they are not affected by hand perspiration.

E-strings don’t unravel but they can go dark or tarnish and the surface can get rough due to perspiration. When having these problems, trade your e-string for the gold plated PI01AU, the platinum plated PI01PT or the chrome-steel Dominant string nr. 129. All of them stand the test of time and perspiration. The difference between those three strings: gold-plated strings have a warm sound while still retaining great clarity. Platinum-plated strings convince with the same clarity but offer more power at the same tension level. Chrome-plated strings are a good budget solution to platinum-plated strings. They are more powerful than gold-plated strings, but also a bit more metallic sounding.

All these strings work well together in any chosen combination. They are all perfectly attuned strings with identical tensions and enable you to modify your tone and assemble your sound while solving the corrosion problem. A small sneak peek into the future: Soon Thomastik-Infeld will also offer a corrosion resistant chrome-wound string with a synthetic core!

Do you have a burning question about strings? Email the experts at ask@thomastik-infeld.com

No comments yet