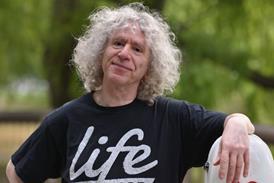

Dutch violin maker Koen Padding, whose passion for classical

varnish was known to many luthiers through the products he sold

under the Magister brand name, died suddenly last week. He was in

his mid-fifties.

Padding trained at the Newark School of Violin Making in the UK and

then spent eight years restoring classical Italian instruments for

several leading European shops. During the 1980s he joined a team

of maker–restorers working under Roger Hargrave in Bremen. He

returned to the Netherlands to concentrate on making new

instruments, but began to devote much of his time to researching

and experimenting with violin varnishes.

In the early 1990s he began selling some of his varnish, and this

enterprise developed into Magister Varnish Products, which today

comprises a range including primers, sealers, grounds, paints and

oil varnishes.

Padding advocated a five-stage coating system (priming, sealing,

grounding, painting and varnishing) that he believed classical

Italian makers adopted from a method used by the Byzantines. In an

interview with Roger Hargrave in the March 2005 issue of The

Strad he emphasised the importance of the whole coating,

rather than just the varnish on top:

'A coating is a system of layers and this system influences

both the appearance and performance of an instrument. Once you

begin to think of the violin's outward appearance in this way, then

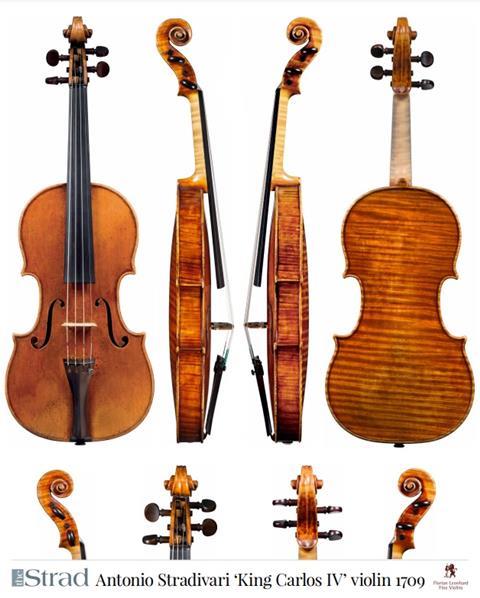

it becomes apparent that the similarities that make us classify all

the different 'varnishes' from Amati to Guadagnini as 'classical

varnish' have more to do with the first few layers of these

coatings than with the actual varnish itself.'

As well as scouring historical sources for varnish recipes and

examining classical instruments, Padding was very hands-on in his

experiments, spending hundreds of hours testing different oil and

resin combinations. He said: 'You have to smell, even taste, your

materials and experience how they behave under different

conditions. Just as a violin maker needs to understand his wood or

a blacksmith get the feel of a particular batch of iron in order to

get the best results from their work.'

- News

- For Subscribers

- Student Hub

- Playing Hub

- Directory

- Lutherie

- Magazine

- Magazine archive

- Whether you're a player, maker, teacher or enthusiast, you'll find ideas and inspiration from leading artists, teachers and luthiers in our archive which features every issue published since January 2010 - available exclusively to subscribers. View the archive.

- Jobs

- Shop

- Podcast

- Contact us

- Subscribe

- School Subscription

- Competitions

- Reviews

- Debate

- Artists

- Accessories

No comments yet