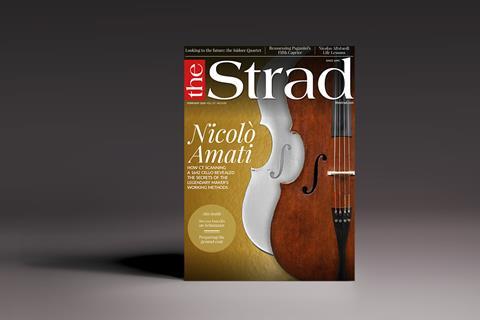

As the protective features of violin cases grow ever more sophisticated, Tom Stewart looks at how the latest innovations stack up against more classic technology

In some ways the violin case hasn’t changed all that much since the time of the Italian masters. Constructed in hard but supple deciduous woods like poplar and covered in calf leather, early cases provided a blueprint for the makers who followed. The protection these examples provided was, however, very limited, and vast improvements have since been made. Recent developments, particularly in materials used to construct the outer shell of cases, have made it possible to shield the instrument against changes in temperature and humidity, with sophisticated suspension systems and practically indestructible casings guarding against all but the most violent impacts. With temperature and humidity monitors, it is now possible to follow the climatic conditions inside the case in real time on your smartphone. And if the case is stolen with the violin inside, motion-activated alarms are triggered while concealed GPS trackers chart the case’s location. But while most makers have incorporated at least some of these new possibilities into their designs for what Negri Cases founder Luis Negri calls ‘the only piece of luggage you use 365 days a year’, not all of them are convinced that, when it comes to safety and security, newer really is better.

‘Just because a material is found on board new planes and spacecraft, it doesn’t mean it’s best for protecting your violin’ – Dimitri Musafia

The shell – the barrier that comes between the violin and the outside world – is where much of the innovation has been focused, with the introduction of new materials including complex three-ply ‘sandwich’ structures and impact-resistant polycarbonate plastic. Despite this, Dimitri Musafia, founder of the eponymous Cremona case maker, insists that wood remains the best option. Like those made in Stradivari’s workshop, Musafia’s cases are constructed from poplar. The company uses wood laminate, a kind of plywood made using resin and high pressure to bond together layers of wood, each of which is rotated so that its grain travels in a different direction from that of the layer underneath, improving the tensile strength of the finished result. ‘Our extensive tests,’ explains Musafia, ‘have looked at carbon fibre, fibreglass, Kevlar, and composite plastic shells of both our own and other people’s design. None of these materials gives the same overall protection as properly engineered wood laminate.’

According to Musafia, wood laminate not only gives the best strength-to-weight ratio but also does the best job of insulating the inside of the case from undesirably hot or cold, or dry or humid conditions outside. ‘Wood is 30 times more thermally insulating than carbon fibre,’ he says. ‘Because carbon fibre has widespread uses in the aerospace industry, for example, it’s very easy to market as a “material of the future”. But just because a material is found on board new planes and spacecraft, it doesn’t mean it’s best for protecting your violin.’Negri is another maker who exclusively uses wood laminate. Carbon fibre may be ‘more robust’, he says, but the fact that it offers little or no protection against the changes in temperature and humidity that can result in open joints and even cracked wood makes it a less than perfect substitute. ‘One of the best things about wood is that it allows for the exchange of air between the inside and outside of the case, letting the instrument “breathe” at the same time as protecting it from temperature changes,’ he explains. ‘Carbon-fibre shells, on the other hand, are completely impermeable and so require humidity detectors on either side so that the differential can be monitored.’

‘The best way to create a light shell was to keep each layer as thin as possible’ – Werner Häcker

Swiss cellist and developer Curdin Coray also favoured wood laminate for the CC case he designed for Beijing-based For-Tune. ‘Some people look at the weight of the case first,’ he says, ‘and artificial materials like carbon fibre are obviously much lighter than wood. But our case is still only 3kg, which isn’t too heavy at all.’ Musafia agrees that wooden shouldn’t necessarily mean heavy. ‘If you started from scratch today with the aim of making a basic lightweight wooden case, you would finish up with a product somewhere around 4kg,’ he says. ‘Finding the right balance between strength and weight is complicated and takes time, but by trying different thicknesses of wood and different glue recipes, we have managed to bring the total weight down to less than 2kg, including the protective outer fabric layer.’

The challenge for Coray came when he decided the case should have no ‘space-wasting’ corners. ‘Creating a rounded and elegant shape using wood takes a lot of time and effort,’ he explains, and Musafia, too, highlights the importance of a ‘highly skilled and motivated workforce’ for building cases almost entirely by hand. This goes some way to explaining why wood-laminate cases, although heavier than many of their competitors, are nearly always more expensive. So what of the alternatives? If there’s one thing most makers seem to agree on, it’s that if maximum protection is a priority, carbon-fibre cases must now compete with those made from a host of new high-tech plastics. As a material, carbon fibre is difficult to produce safely and its restricted colour palette offers few possibilities for eye-catching design. French maker BAM turned to polycarbonate, and recently created the first violin case with a 100 per cent polycarbonate outer shell. Polycarbonate, often used to make suitcases, is even stronger than carbon fibre, but comes with its own difficulties of manufacture. ‘It’s incredibly dense and must be heated to around 180C before it can be worked with,’ explains BAM director Robert Goetz. ‘ABS plastic, for instance, melts at a much lower temperature, and is therefore far easier to shape around a mould. But tests carried out to ISO (International Organization for Standardization) regulations show that polycarbonate has a far superior tensile strength, which is why we chose it as the material for our newest product line.’

Previous attempts to incorporate temperature and humidity monitors in our cases haven’t really worked and players don’t seem to miss them now they’ve gone’ – Robert Goetz

Underneath the outer polycarbonate skin of these BAM cases is a thicker supportive layer of PVC foam, and the three-ply structure is completed with a sheet of PETG plastic beneath that. ‘In time,’ says Goetz, ‘all our cases will be made out of polycarbonate. It combines the lightweight properties of carbon fibre with the highly insulating characteristics of wood. And if you took a golf club and swung it at two cases, one made of polycarbonate and one made of wood laminate, I know which of them I would rather contained my violin.’ German manufacturer Gewa also uses a ‘sandwich’ of three materials. Gewa’s cases started out, like those made by Musafia, constructed out of wood. Then they covered the wood with an ABS foil, before doing away with wood altogether in favour of a crush-resistant polymer. The new Air case features a layer of high-density polyurethane foam that both insulates and cushions the break-resistant plastic shell above. A layer of strong, shiny acrylic forms the outermost surface. ‘Of course, we wanted to create a light shell,’ explains Gewa product manager Werner Häcker. ‘The best way to do that was to keep each layer as thin as possible. That meant forming each of them separately, a process that requires eight separate moulds.’ At just 1.7kg, the case is certainly among the lighter examples available but, according to BAM at least, the protection offered by standard polymer-based structures cannot compete with polycarbonate for strength and rigidity.

For Coray of For-Tune, the shape and internal layout of the case were the prime candidates for change, not the mixture of hard and light woods it was built from. The CC case is 4cm wider than most models, with space for a bow to lie flat, held securely inside a special compartment next to the instrument. ‘Accidents happen when the case is arranged in the usual way, with the bows above the violin,’ he says, ‘and since the layout removes the need for the bow to be clipped in place, the player is able to lift and replace the bow using only one hand.’ In a market that often seems to prioritise reduced weight and size, not all players will welcome the expanded dimensions, but those who do will find that the CC case is large enough to accommodate the standard-size printed music that is too big for most others.Besides innovation in the materials used to construct the external body, the other significant development in violin case technology is the gadgets that are becoming commonplace inside. These fall into three categories: thermometers and hygrometers; alarms that alert owners if the case is moved or opened without their knowledge; and GPS systems that can track the case’s location. Musafia’s ‘Full Protection’ system, for example, includes all of these devices, but other makers (and players) are less sure that the technologies are individually effective. Coray argues that even a concealed GPS system is rendered useless by a thief who, aware that one will be hidden somewhere within the case, simply removes the instrument at the first opportunity. ‘Their increasing ubiquity,’ he says, ‘will only make the problem worse.’ A possible solution, he suggests, would be to design a case that was impossible to open by those whose motives for doing so were nefarious. ‘In the future, a titanium case with highly sophisticated locks could be one way of preventing thieves from simply dumping the case as soon as they have taken the instrument.’

Incompatibility with wireless systems is a reason why makers are leaving carbon fibre behind

Apart from the prohibitive cost and impractical weight of a hypothetical metal case, titanium would prevent any GPS device inside from transmitting properly. Indeed, incompatibility with wireless systems like Bluetooth is another reason why makers are leaving behind carbon fibre, which inhibits radio and other electronic waves. Wood, polycarbonate and other plastics, on the other hand, allow such signals to pass through unhindered, marking out those materials as well suited to the emerging trend for including electronic security systems inside violin cases. And while a quad-band GPS system can transmit data to a mobile phone from most parts of the world, not all makers use these high-specification, high-cost models. It is therefore important that anyone who decides to invest in a geolocation device ensures that theirs provides sufficient coverage for their needs. They also require a constant power supply, with batteries that must either be recharged or replaced. The additional weight this represents might put off players for whom any additional weight is to be avoided.

Batteries have, however, shrunk in recent years, increasing the range and number of devices that can be included in a case design. ‘They’re getting smaller and smaller,’ says Negri, ‘meaning that we can collect more and more information about an instrument and its surroundings.’ The research and development costs involved in reducing the size and weight of electronic components are of course reflected in their price, and the price of cases that feature them. But, as has happened with similar technology used to monitor the way a driver handles and cares for their vehicle, the data collected can help to lower insurance premiums. Indeed, UK instrument insurance specialist New Moon offers a discount to clients using Negri’s latest model, on account of the additional protection it affords. Hygrometers and thermometers have been commonplace inside cases for far longer than GPS systems. What is relatively new is the ability to monitor humidity and temperature remotely using a Bluetooth-enabled smartphone and a system such as D’Addario’s Humiditrak sensor and app. BAM, Gewa, Musafia, Negri and For-Tune all offer hygrometers (often in collaboration with accessories makers such as D’Addario) and reserve dedicated spaces inside their cases to house them. Musafia’s cases, as well as incorporating hygrometers into their design, can also be fitted with a kind of valve system that, according to Dimitri Musafia, regulates internal humidity.

Testing how two cases – one closed and the other 0.5cm open – responded to direct sunlight, Musafia observed that as the two cases heated up, the relative humidity doubled inside the sealed case and reduced inside the other. ‘Neither result was desirable for maintaining uniform and optimum conditions for the instrument, but the test highlighted the fact that a completely sealed case can very quickly become a pressure cooker for the instrument inside.’ The solution was to drill a series of small holes along the side of the case and cover them with a layer of watertight but not airtight fabric that allows the warm, humid air to escape, compensating for the raised dew point of the sealed case.

Alarms, both silent and ear-splittingly loud, are also becoming more and more common. When switched on, these alarms are triggered by movement above a particular threshold, and either send an alert direct to their owner’s mobile phone or emit a siren to alert passers-by. Not everyone will feel comfortable knowing that backstage their case is poised to alert everyone around to its presence, but these alarms, which use motion sensors to detect movement, are another line of defence against theft. They have their detractors though, among them Goetz, who believes that alarms, particularly the motion-activated kind, are too unpredictable and temperamental to be trusted properly. ‘Tracking devices, however,’ he says, ‘do make sense, and we’re currently working on one to suit our cases perfectly. There are two questions with all this technology – does the device really work, and do people know how to use it properly? Very often the answer to at least one of these is no, and that undermines the argument for including this expensive (and sometimes heavy) technology. Previous attempts to incorporate temperature and humidity monitors in our cases haven’t really worked and players don’t seem to miss them now they’ve gone.’

While the violin has, for centuries, remained basically unchanged, the way we protect our instruments is evolving more quickly than ever before. Innovation in materials technology has led to a host of new possibilities for constructing an effectively indestructible outer shell, the first line of defence for the violin inside. Information provided by sensors, alarms and GPS systems ostensibly allows owners to track their instrument in minute detail, although their effectiveness is not always indisputable. ‘Cases are about compromise,’ reflects Negri. ‘You have to strike a balance between a range of different – but equally valid – priorities. Musicians expect their case to be very sturdy and durable at the same time as being light and elegant.’ Some people, like those who prefer wooden cases, believe it is better to build modern technology into the traditions of the past, while others are eager to try out new things for the first time. For players who fall somewhere between these two camps, a useful combination of features can usually be found to suit their particular requirements.

No comments yet