In this extract from the August 2021 issue, Joseph Curtin discusses how he experimented with adjustable necks, progressing from the various changes made in connecting an instrument’s neck to its body since the Baroque era

Photos: Lonny Marino

FIGURE 10 Digital rendering of a simple tilting neck design using three screws. The neck is reinforced with carbon fibre along its length, the heel with vertical-grain maple, and the back face of the top-block with a horizontal-grain maple strip. FIGURE 11 A spring-pin keeps the neck and body aligned and in place even without string tension. Neck projection is adjusted using the screw near the bottom of the heel . FIGURE 12 Adjustments to the centring of the fingerboard can be made via the port on the bass side of the heel.

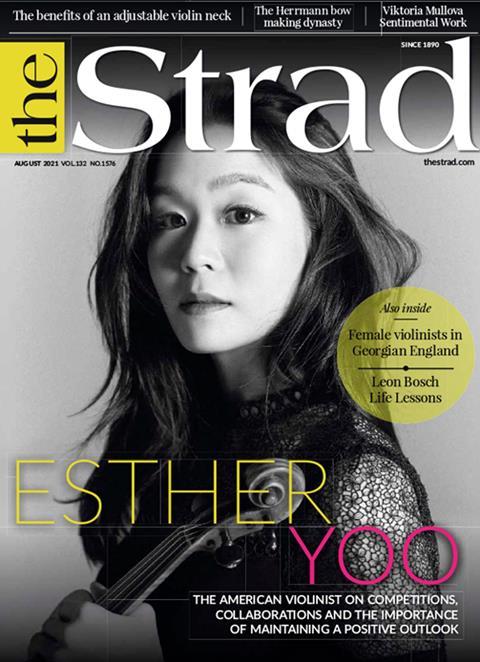

The following extract is from The Strad’s August issue feature ’Neck Setting: Adjustment to change’. To read it in full, click here to subscribe and login. The August 2021 digital magazine and print edition are on sale now

Some 25 years ago I began experimenting with adjustable necks. The earliest was a simple sliding design used on a few violas. Adjusting it required unstringing the instrument and inserting a long key through the endpin hole into a screw in the top-block. Though far easier than resetting the neck, it didn’t seem worth the eccentricity, so I later converted them to traditional necksets. From there I moved to tilting designs and made half a dozen prototype variations before arriving at what seemed an elementally simple model (shown as a computer rendering in figures 10 and 11). The neck pivots about two set screws recessed into the neck. These control the centring. A third screw, which adjusts projection, goes through the heel into a threaded insert in the upper block. Simple as it is, the basic principle works extremely well and can be implemented in numerous ways.

The downside is that when the strings are loosened, the neck can flop around on the adjustment screw. This can be remedied by fixing a spring-steel pin into a brass insert in the neck heel, as in figure 10. The other end slides into a brass tube in the upper block. The flexibility of the pin allows a few degrees of tilt while keeping the neck securely in place even without string tension. When the strings are tuned up, the assembly becomes rock solid. Adjustable necks typically give the player control over neck projection only, but the addition of a small port in the bass side of the heel (figure 12) makes the centring of the fingerboard adjustable too.

Photos: Lonny Marino

One implementation of an adjustable neck design using three screws and a spring-pin. For player comfort, the fingerboard has been widened along the upper reaches of the treble side. As with virtually all adjustable designs, the button is not attached to the back.

An adjustable neck has advantages beyond the obvious. During the initial set-up, the maker can try bridges of different heights. Once the optimal height is discovered, it need never be changed. Also, a quickly detachable neck makes it significantly easier to remove the top and back for repairs. With larger instruments it becomes feasible to detach the neck for transportation. More speculatively, a player could swap necks on a single instrument, going Baroque for one performance and modern for the next.

It is interesting to compare the development of the violin with that of the steel-string guitar, as the two share a similar narrative trajectory, with the guitar’s compressed into a single century. The steel-string emerged as a distinct instrument in the early 20th century. A pre-World War II ‘golden age’ was followed by ongoing attempts to recapture the sound and feel of the most sought-after instruments. Guitars played by famous musicians appreciated wildly. In 2020 a rare 1959 Martin D-18E sold at auction for $6 million. Okay, it belonged to Kurt Cobain, but that is saying no more than that ‘Il Cannone’ belonged to Paganini. Like violins, guitars have neck issues. Long necks together with high string tensions make reinforcement mandatory. Metal truss rods are widely used, typically with an adjustment nut that lets the player alter the scoop of the neck. In 2007 Martin introduced a line of instruments with a ‘continually adjustable neck’. The design is strikingly similar to James Ham’s.

The disadvantage of adjustable necks lies not with their utility but their novelty. An innovative neckset may be exciting for the inventor and useful to the player, but unless its workings are transparent and maintenance-free, it may be difficult to get anyone other than the original maker to maintain or re-sell the instrument.

That, at least, is the underlying fear in the violin world – though if this world were truly as conservative as is commonly assumed, we would still be playing Baroque instruments. Ironically, the apparent immutability of the violin rests on its capacity to retain its identity despite extensive structural modifications. Changes are widely accepted only when they solve significant problems for players and/or makers. The modern neckset solved one set of problems but introduced another. A well-designed adjustable neck can eliminate neck-related problems altogether.

Read: Neck setting: Adjustment to change

Read: ‘Noah’s violin’ to take to the Venetian canals in September

-

This article was published in the August 2021 Esther Yoo issue

The American violinist on competitions, collaborations and the importance of maintaining a positive outlook. Explore all the articles in this issue . Explore all the articles in this issue

More from this issue…

- American violinist Esther Yoo

- The benefits of an adjustable violin neck

- Bach’s Solo Violin Partitas

- The Herrmann bow making dynasty

- Female violinists in 18th-century England

- Making accurate arching templates

Read more playing content here

-

1 Readers' comment