- News

- For Subscribers

- Student Hub

- Playing Hub

- Directory

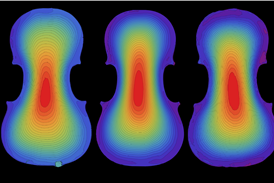

- Lutherie

- Magazine

- Magazine archive

- Whether you're a player, maker, teacher or enthusiast, you'll find ideas and inspiration from leading artists, teachers and luthiers in our archive which features every issue published since January 2010 - available exclusively to subscribers. View the archive.

- Jobs

- Shop

- Podcast

- Contact us

- Subscribe

- School Subscription

- Competitions

- Reviews

- Debate

- Artists

- Accessories

Violin making in Seoul: Gangnam style

Over the past decade, a wide community of violin and bow makers has grown up in the Seocho district of Seoul. Luthier Hagit Gili Gluska speaks to colleagues young and old, both local and from overseas, who have made this area their home

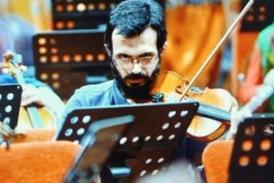

In the wide avenues of the big metropolitan city of Seoul, among the shiny skyscrapers of the famous Gangnam area, all is hot, humid and noisy – from the buses to the deafening sound of cicadas. But turn into a small neighbourhood and suddenly everything is quiet. Between the three-storey buildings made of red building blocks and green mountains on the horizon, the only sounds are the sweet piano and violin music emanating from the shops. Around every corner you see violins. This is the Seocho district, home to more than a hundred violin and bow makers who have been trained all over the world – from Korea to Italy, the UK, Germany, France and the US. There are also hundreds of other music-related businesses: rehearsal rooms, conservatoires, private schools and equipment stores for musicians, all in the shadow of the Seoul Arts Center, Korea’s best-known concert hall. The first time I came here I stood in the heart of the main neighbourhood feeling like a child in a candy store. Here is a microcosm of the violin making industry with a Korean scent.

As South Korea was only founded as a republic in 1948, it lacks the centuries-long traditions of violin and bow making that European countries have. In the 1980s Jun Suh Park, today the head of the Maestro Violin Makers Association of Korea (MVAK), returned to the Seocho district after studying violin making in Chicago with his uncle Tschu Ho Lee, a well-known luthier who immigrated to the United States and helped co-found the Chicago School of Violin Making (CSVM). ‘There was nothing here in Seocho back then – just two or three violin makers,’ Park recalls. His workshop, located in one of the buildings in the northern part of Seocho, is actually a residence apartment in a five-storey building where he lives with the rest of his family, mostly all luthiers. The building also houses his sister Min Suh Park, regarded as the first female violin maker in South Korea, and her husband Kevin March, an American maker.

Unlike the romantic stories of many luthiers regarding their decision to pursue this art, Park is modest about his first steps in the trade. ‘I was young, a member of a family of violin makers, so I learnt the profession,’ he shrugs. When he returned from his studies in the US as a young maker in the 1980s, the environment was very different as he remembers: ‘In those days, musicians mainly came from the wealthy part of the population, people who went to study in Europe or the United States, and purchased expensive antique musical instruments there. Whenever they needed a repair or sound adjustment, they had to fly to get it taken care of in Europe, or settle for an unprofessional repair job here in Korea.’ When he returned to South Korea he found a lot of work repairing violins. ‘We worked from morning till night and customers kept coming, so I didn’t have to look for work,’ he laughs. ‘Work was looking for me!’

’Students who graduate from violin making schools abroad will have a very hard time surviving here economically’ – Min Suh Park

With the construction of the Seoul Arts Center in 1988, more and more violin makers gathered in the area, but there was still plenty of repair work for everyone. The main change came in the late 1990s when many Koreans who had been trained as violin makers abroad returned to their homeland and the competition for the share of restoration and repair work increased significantly. ‘It might be that some musicians, parents of students and teachers saw us, the first generation of violin makers here in South Korea in the 1980s, and came to the conclusion that this is a very profitable business – at least more than playing music,’ says Kevin March. ‘So more and more Koreans went to study violin making abroad, and when they came back to Korea, the competition for restoration and repair work was rising.’

Little by little, many violin makers had less repair work to do, and more free time to fulfil the dream that many violin makers have – building new instruments. This was the start of a new industry in Korea of hand-crafted bowed stringed instruments. Before that time, the trade in South Korea and China had been synonymous with cheap factory-made instruments. It was not an easy start for the new generation of makers: Korean customers still preferred European instruments, and therefore selling Korean work at a profitable price was challenging…

Already subscribed? Please sign in

Subscribe to continue reading…

We’re delighted that you are enjoying our website. For a limited period, you can try an online subscription to The Strad completely free of charge.

* Issues and supplements are available as both print and digital editions. Online subscribers will only receive access to the digital versions.