- News

- For Subscribers

- Student Hub

- Playing Hub

- Podcast

- Lutherie

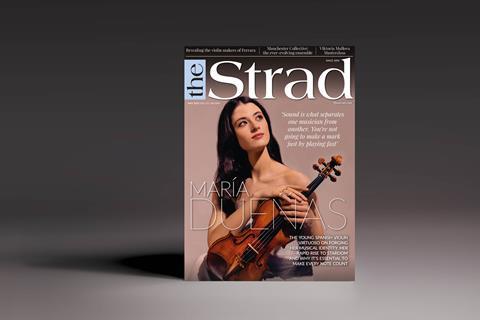

- Magazine

- Magazine archive

- Whether you're a player, maker, teacher or enthusiast, you'll find ideas and inspiration from leading artists, teachers and luthiers in our archive which features every issue published since January 2010 - available exclusively to subscribers. View the archive.

- Jobs

- Shop

- Directory

- Contact us

- Subscribe

- Competitions

- Reviews

- Debate

- Artists

- Accessories

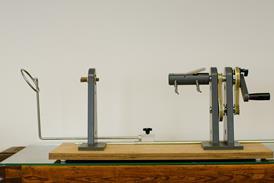

Should violin makers embrace cutting edge computer analysis?

Violin maker Sam Zygmuntowicz explores how high-tech ways of analysing violins and their sound could help makers and even influence the future forms of instruments

Already subscribed? Please sign in

Subscribe to continue reading…

We’re delighted that you are enjoying our website. For a limited period, you can try an online subscription to The Strad completely free of charge.

* Issues and supplements are available as both print and digital editions. Online subscribers will only receive access to the digital versions.