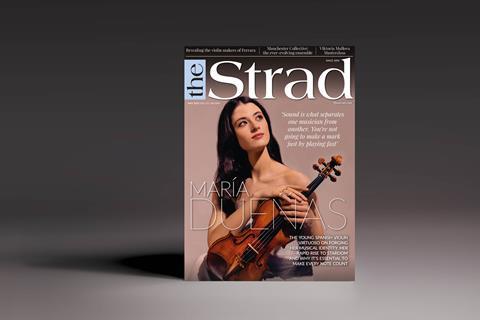

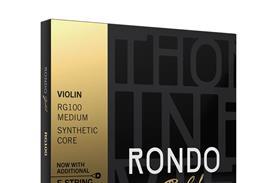

There are hundreds of strings available on the market already, and new releases seem never ending. But just why are these developments happening, how necessary are they, and how are musicians involved in that process? Pauline Harding asks string manufacturers and testers worldwide

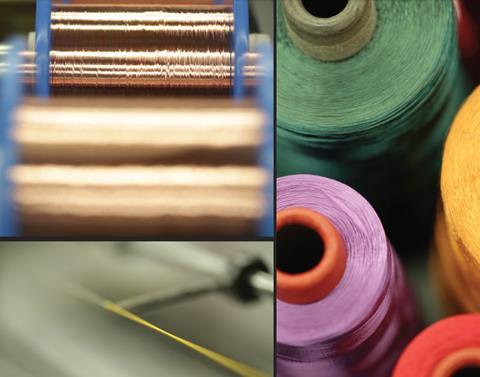

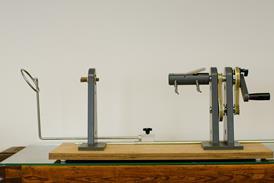

‘Stand back,’ warns Laurits Larsen, founder and CEO of Larsen Strings. We’re at his factory in Sønderborg, Denmark, and he’s about to show me how he made his first cello string almost 30 years ago, in his garage, using a winding machine originally used to make piano strings. The machine itself is around a hundred years old, from a time when, he quips, health and safety standards were low. He attaches a steel wire between the two wheels, winds the machine into action and carefully coats the core in a dampening glue, then pulls a strip of thin metal ribbon along the spinning centre. When he has finished, he examines the winding under a pocket microscope to check that it is even, spins it through a piece of sandpaper to smooth the surface, and wraps the ends with brightly coloured cotton. He proudly dangles the new, hand-made string in front of me.

Over the next few hours I explore his factory, where enormous, automated machines spin and wind all manner of metals and synthetic materials into strings. I have been playing the violin since I was four years old, and yet suddenly I realise that never before have I really thought about what makes a string. With numerous products available on the market, why are so many new versions still being created? And would understanding more about what goes into a string, and why, make it easier for me to guess what sound would come out once it was on my instrument? I decided to investigate. ‘If you say nothing can be improved, you should close your shop,’ says Larsen. ‘New technologies and materials continuously offer us new possibilities. Bigger concert halls are being built, but the violins themselves do not change, and many need more brilliance, volume or carrying power.’ D’Addario’s product manager Lyris Hung says that sometimes her team will create a new experimental string without an audience in mind; but in general, manufacturers first research what players want and need. D’Addario, Thomastik-Infeld and Jargar all tell me they speak to a wide range of players and industry professionals to gain feedback on an ongoing basis, to find out what they use, and what they think could be better.

Once a new development project begins, manufacturers work closely with musicians in what Bernhard Rieger, Thomastik’s retail and distribution manager, calls ‘a collaborative learning process from the beginning’. To develop its Kaplan double bass strings, for example, D’Addario enlisted the help of Kurt Muroki, a double bass professor at the Jacobs School of Music in Indiana, US. Muroki tried around 40 prototypes at D’Addario’s New York headquarters and gave on-the-spot feedback; he then took strings away and played them for up to two months before returning to discuss them further. Once they had refined the set’s basic design, they asked other bassists to test them too.

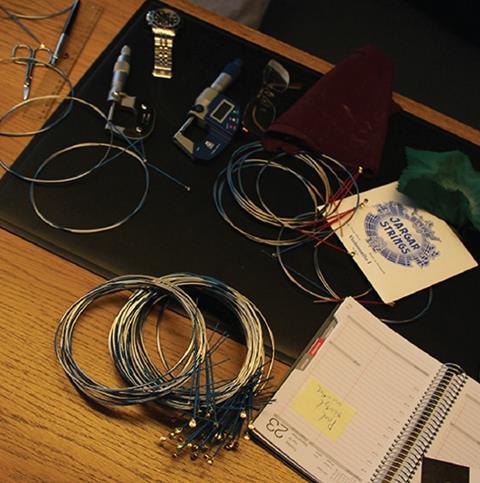

Testers can number between the tens and the thousands for each product, depending on the size of the target audience. D’Addario, Jargar and others like to collect answers to specific questions, with a focus on tone – brightness, darkness, the spectrum of colours – as well as the flexibility of the sound; the feel of the string under the bow and the left hand; smoothness and consistency; and projection. Bohdan Warchal, owner of Warchal Strings, prefers to leave musicians to make their own comments: ‘The more questions you ask, the more you unintentionally dictate their answers,’ he says. In all cases, once the strings are on the market, users send unsolicited feedback, so the process is never-ending. ‘Many of the top players will know if they do not like a string within a few seconds of playing,’ says Larsen. ‘If they just keep playing and playing, then you know you’re on to something.’

In an industry populated by instruments with a design that is over 300 years old, innovation is not always popular

During testing, Larsen sometimes notices problems before the players do. ‘When I see the bow arm is raised,’ he says, ‘I know we have to work on response, because they are having to work too hard but have not yet realised it.’ He will then tweak the strings as many times as necessary. ‘We come up with rough ideas, we share opinions, we take the strings back home and then we meet with the musicians again. We continue until we and the musicians are satisfied.’ That said, some players are more reliable testers than others, and over the years, he reflects, ‘you learn not to rely too much on these people. Many years ago a well-known cellist thanked me for the new A strings I’d sent him, but said there was a rattling sound. I sent him new strings, but when they arrived he called again to say the rattle was still there. I asked him to go to a violin maker to see if the instrument had become unglued. One week later he called again: “Everything is just fine! Thank you for sending the strings.” We asked, “Well, did you go to the violin maker?” And he said, “No, I went to the doctor.” The doctor had removed some wax from one of his ears; after that, the cello sounded fine.’ Of course, even ‘reliable’ players vary in and among themselves. ‘Sometimes they use words that we never associate with strings, like squishy and muffled; or words they’ve made up,’ says Hung. ‘We have to establish a rapport with each player – we can’t just say “bright” or “dark”, because if I listen to something and I say it’s bright, and someone else doesn’t think it’s bright, we are using two different vocabularies to define the same thing.’ To gain a better understanding of their language, Hung often asks players to describe the instruments and brands they are already using, as a benchmark.

This is helpful, but not foolproof: one string will sound different on different instruments, or even on the same instrument with different players, in different acoustics, under different bows, at different stages of wear, and so on. It is important to gather wide-ranging perspectives, from players with everything from cheap factory instruments to Strads; amateurs to professionals; soloists, chamber musicians, orchestral players; and in different acoustics – both when the strings are new and after around three weeks’ use.

Working in a shop with varied customers and three rooms with different acoustics helps Vienna-based luthier Marcel Richters, who has collaborated with Larsen for the past two years, to gain a good impression of how strings function across the board. ‘Give one violin to three different players and sometimes you think it can’t be true that it’s the same instrument,’ he says, also noting what a difference the acoustic can make: ‘Quite often we have a feeling that an instrument is incredibly powerful when we hear it close by or in a small room, when in a hall it’s quite the opposite. The player, instrument and set-up all play a role, and at the beginning of it all is the string.’

This is a concept that Muroki struggled with when developing the Kaplan set. His c.1665 Amati double bass is very different from his 2007 Arnold Schnitzer, and strings reacted so differently on each that it was difficult for him to give consistent feedback. ‘I wasn’t sure if I should focus on creating a string that was perfect for me, for one instrument, or one that would be more general,’ he says. ‘In the end I put a lot of pressure on myself to try to find something that would really work for D’Addario, and I almost had to disregard certain aspects of my own personal taste.’Once feedback has been interpreted and collated, a new challenge arises: how to turn words into science. Most of the manufacturers have ‘sound labs’ where they develop their own theories and techniques. In general, Warchal insists that the process isn’t complicated: ‘Every abstract term has an equivalent in the string formula,’ he says. ‘If a player indicates poor playability, for example, there may be something wrong with the tension, torsion stability or surface friction. You simply try to compensate for any weaknesses by altering the construction.’

Science is key, and each company has its own custom-built tools to help. At Thomastik, says Rieger, ‘we have analysed the movements of strings with high-speed cameras; researched the connection between the bow and the string; run a research programme to investigate materials, production methods and quality control; researched the connection between string, bridges and instruments; and much more.’ Larsen, too, has a sound laboratory, where he and his colleagues make string measurements and compare that data with player feedback to see how they correspond.

‘A set of violin strings can have a pull equivalent to between 25kg and 30kg’ – Marcel Richters

When it comes to changing a string’s sound, adaptations tend to involve a mixture of scientific knowledge, trial and error, and experience. It can be helpful to start with benchmarks, says Hung: if players think one string is too dark and another too bright, they can look at the construction of each and manipulate the brightness by tweaking their physical characteristics accordingly. For example, says Erik Martens, Jargar’s administrative manager, ‘Low or high tension tend to create either a very bright or a more muddy sound. Then there are the winding materials: for instance, chrome winding might give a brighter sound, and aluminium a warmer sound.’ Another area of concern among players is loudness. Here, increasing the tension helps too – although that should be done with caution. ‘A set of violin strings can have a pull equivalent to between 25kg and 30kg,’ says Richters. ‘A certain percentage of that pushes down on the bridge and the body, and some of the more fragile older instruments will be overwhelmed by this instead of getting louder. At a certain point they will close up.’ He works with Larsen to try to build powerful, lower-tension strings.

Other player feedback often relates to string response. Here, the diameter of the string is important: the thicker the string, the harder it is to ‘start up’; but if a string is thinned to make it more responsive, other elements must be changed too. ‘Let’s take a full-size violin A,’ says Hung. ‘The pitch and length are fixed, so within that we have to have a certain amount of mass to create the A pitch. If I add mass to the string without changing the length, the pitch goes down. To crank it back up, I have to add more tension. Another option would be to substitute the material for a higher-density metal, to get the same amount of mass into less space; or we could use a thinner wrap to create the same amount of mass in the same amount of space, to keep the tension similar while reducing the diameter. We can adjust the tension by doing any of those things and adding mass with or without adding diameter. It depends on the combination of materials.’ Muroki was amazed at how Hung and her team were able to tweak his strings in accordance with his ideas. ‘I would describe what I was looking for,’ he recalls. ‘Then they would say, “We’re going to go out for a few minutes and then come back with a new string.” They predicted what the materials would do, and they were 99 per cent correct. Did we come to the ultimate string? Of course not. But when everything is even and comfortable, there comes a point where research and development have to stop and the string has to be released. My ideal would be a thinner string that sounds like a thick string, to have something that responds quickly but still has enough mass to it, but I realise there are physical limitations!’

Although different materials and windings can cause certain predictable effects, the variables are seemingly infinite. For example, chrome wound and dampened one way might produce a brighter or darker sound than aluminium wound and dampened in another, or vice versa; a string with tightly wound coils is likely to sound more dampened than a string with widely spaced winding, because the materials are in greater contact with one another and absorb vibrations. ‘The winding angle can also affect the stiffness of the string, bow response and sound,’ says Hung. ‘If we angle the windings, there’s less room for the string to stretch; if they’re at less of an angle, the string acts more like a Slinky toy: there’s more stretch to it, and that has an effect on a lot of different aspects of the string.’ Not only that, but strings can be wound multiple times with different types of materials at different angles, and so on. Even Warchal confesses that whatever he does, ‘there is still the chance of being surprised’.

String engineers also face barriers: in an industry populated by instruments with a design that is over 300 years old, innovation is not always popular. ‘If a violin A string feels like an E string, it can be disconcerting,’ says Hung. ‘It doesn’t matter how it sounds: it just feels weird, and a lot of people will react to that before they’ve even put their bow to the string.’ If it feels strange, the chances are that players won’t buy it – and if it’s unlikely to sell, manufacturers will be reluctant to make it in the first place, whatever its potential benefits. In the end, instinct and a good understanding of how players want their strings to sound and feel are just as important as the technology itself. Even a theoretically perfect string might sound awful or feel uncomfortable to play. ‘It takes more to make great strings,’ says Rieger. ‘We listen with our hearts to understand musicians’ opinions. I always begin with the sound in my ears and a feel under my fingertips. From there I start with a certain design, which mostly fails at first. Then I improve it until I have met my goal. It’s like practising – simply an interactive process.’So would a better understanding of the science behind the strings help players to make better choices about which strings to use? D’Addario runs ‘Strings 101’ clinics, with the aim of helping players and luthiers to choose strings more intelligently. ‘We talk about the materials,’ says Hung, ‘as well as tension, damping, diameter, what all that means and how it’s controlled; what causes wolf notes and E string whistling; how strings settle in, why they wear out and why we need to change them.’ Perhaps, she says, this will inspire players to look beyond the descriptions written on string packaging, encourage them to do a little research and help them to try strings with a more open mind.

Yet most musicians are not scientists, argues Larsen, and such knowledge has limited use. Some brands, including D’Addario, Jargar and Larsen, publish basic product data on their websites relating to materials, windings and tensions, and Larsen feels this is sufficient. ‘People want to know about tension, and they want to know all the materials,’ he says, ‘but at the end of the day, even if two strings are made from the same material – for example, steel – it doesn’t mean that they will sound the same, because steel is an alloy and can mean many different things depending on how it is treated. The process is more important than the material.’ This means that, to gain a useful understanding of the science behind the string, players would need to gain a prohibitive amount of information, often comprising trade secrets that string makers are not willing to share.

Perhaps for this reason, string science is incidental for Richters: he prefers to use his ears. ‘There are so many theories,’ he says. ‘A lot of people ask how it’s possible, with all our knowledge and technology today, that Stradivari and Guarneri still have not been surpassed by living makers. You can analyse it and think about it and talk about it, but music is primarily an experience that goes through the ears and into the heart. Instruments are such organic things that theories are only helpful to a degree. Most important is to be able to hear and to feel, to understand the player and instrument, and to be able to find ways to solve problems. I don’t need to know exactly how a string is constructed – I find it interesting, but it doesn’t change my work.’ In this vein, Hung compares strings to wine: understanding the science is all very well, but what matters in the end is the taste, and most people will make their selections based on what they know already, the label, the price and reviews they’ve read. ‘To learn for yourself, you have to experiment and be open-minded,’ she says. ‘It’s just more unfortunate with strings because you don’t get drunk!’

‘To expect to find a full set that is the answer to all your dreams is unreasonable’ – Lyris Hung

Experimenting can be a daunting task, and patience is key. ‘It’s a tough process,’ says Hung. ‘When you look at the breadth of instrument, bow and bow arm styles, and the different musical genres, there’s very little chance that you as a player are going to fall smack-bang in the middle of a string’s intended audience. To expect to find a full set that is the answer to all your dreams is unreasonable. It’s almost like going into any violin shop, picking the first violin off the wall and saying, “This one will be perfect!” You have to open your mind to the fact that more than one type of string, or combination of strings, might work for you; and that sometimes you will have to make a compromise.’Given that it is impossible to create a string that suits everyone, string manufacturers could make variants ad infinitum: a different set for every player on every instrument. By and large, then, the more strings the better – but with such variety available, and little help offered even by better scientific understanding, how can musicians choose? ‘The problem is not so much the vast amount of strings available,’ says Richters. ‘If you have 20 different A strings that you know very well, you can quickly make a choice that might be perfect for an instrument. If you only have two to choose from, you have far fewer possibilities. But obviously there comes a point where nobody can know all the strings. There are many more coming on to the market every year and it gets quite confusing.’

Hung believes the answer is for string companies to work with teachers, who can then pass that knowledge on to their students; similarly, Richters feels the responsibility should not lie with players alone. Many luthiers, he says, hear different strings, customers and instruments on a day-to-day basis, so have a greater understanding of their qualities and characteristics. ‘I see it partly as the responsibility of a good violin maker and sound engineer to advise musicians in an educated way,’ he says. ‘I sometimes call up Larsen and say, “Which one of your strings would you choose if there were such and such a problem?” And since they’ve done so much testing with musicians, they’re usually dead right when they recommend a particular string.’

In an ideal world, of course, string makers would be able to make customised strings for individuals, but at the moment this is no more than a futuristic fantasy. ‘We can’t just write down words, take them back to our factory, put them into a computer and, at the other end, out comes the perfect string,’ says Larsen. ‘It doesn’t work like that, because at the end of the day it’s the human voice and the human ear that decide what we do.’ Nevertheless, Hung drifts into reverie at the idea. ‘Certainly it’s my dream to be able to customise string sets efficiently,’ she says, ‘but right now there’s no efficient way for a string manufacturer to gauge what players need without seeing them, hearing them and trying things out in person, and that’s an arduous and long process.’ The best Hung can do at present, she says, is to meet instrumentalists at one of D’Addario’s string clinics, listen to them play and try different strings on their instruments until they’re happy. ‘Ultimately, I would love to be able to have somebody do a demo video, put some numbers in a machine and instantly have a string recommendation!’ she laughs. ‘But we haven’t quite got there yet.’

Watch:

Testing Larsen strings on two Stradivari violins

D’Addario Orchestral Strings | Farmingdale. New York Factory Tour

Promotional video from Larsen strings, including some clips of the manufacturing process

No comments yet